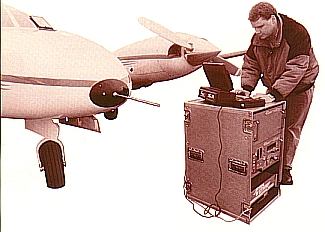

Colin Minty, president of Airwave Electronics, shows off the flame ionization leak detection unit. A special probe, mounted on the front of a fixed-wing plane, draws air directly to the ionizer unit which detects the presence of methane indicating a pipeline leak.

Detecting gas leaks the size of pinholes in a pipeline system 18,829 kilometres (11,700 miles) long is the responsibility of AGTD’s pipeline support and maintenance planning team.

To help meet this challenge, new gas leak detection technologies are constantly being evaluated, to find more precise and cost-effective ways of protecting the integrity of the NOVA pipeline system.

“We’re always interested in looking at new ways of improving our surveillance methods,” says Brian Gillis, interim team leader, pipeline support and maintenance planning. “NOVA has tested infra-red and hydrostatic technologies, but recently has focused on taking a proven ground-based technology and making it fly.”

Gillis is referring to flame ionization leak detection, which has been refined for airborne testing.

Basic chemistry makes flame ionization leak detection work. A flame inside the detection unit is powered by hydrogen. The plane flies along the pipeline and the flame in the unit reacts to methane, indicating a leak.

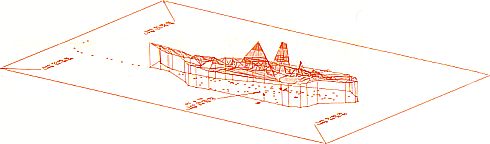

The deepest color at the peak of the plume shows the highest concentration of gas (10 to 12 ppm), pinpointing the location of the leak from the air. |

The challenge is to transfer this technology to a small aircraft with a limited payload. The readings from 61 metres (200 feet) above the pipeline must be taken from undisturbed air (no airplane exhaust) and retain enough accuracy to pinpoint the location of the leak within 100 metres (328 feet).

A local Calgary company, Airwave Electronics, has developed specialized equipment that allows undisturbed air to be drawn directly to the analyzer, using a special probe mounted on the front of a fixed-wing plane. The equipment has also been reconfigured to reduce the weight and size for aviation safety purposes.

Several members of the AGTD pipeline support and maintenance planning team are participating in tests of this technology, which involve releasing a small amount of gas from two valves on the western system near the Knight compressor station. The test showed the gas disbursement plume above the pipeline.

“With this technology, you can fly an entire pipeline system in hours rather than walking or driving the system, so the cost-savings could be substantial,” confirms Gillis.