Efforts to detect pipeline leaks before they result in massive ruptures are creating a lot of interest in a Calgary company that has pioneered a technique to sniff out leaks from the air.

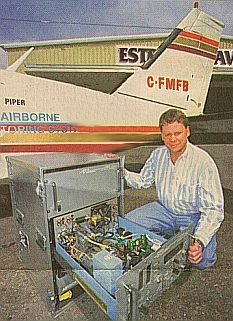

Airwave Electronics Ltd., a 10-year-old firm selling and designing gas detection devices, has developed a system that company president Colin Minty says is capable of discovering pin-hole-sized leaks from 45 metres above the ground.

“What we’ve basically done is taken a proven ground-based system and converted it to work from a plane,” Minty says. “It means companies which previously hired walkers to inspect hundreds of kilometres of pipeline on foot can now do the same thing in a matter of hours.”

Minty, who designed the system, says there was no particular breakthrough just a coming together of several technologies.

Minty’s technology, a flame ionization system, uses basic chemistry to detect pipeline leaks. Methane or any other gas released in a pipeline leak consists predominantly of hydrocarbons.

A probe attached to the front of the aircraft captures samples of air above the pipeline path. Then an onboard unit burns any hydrocarbons in the sample. The burning process releases carbon electrons, which are attracted to a positively charged rod.

“The system measures the number of carbon electrons that attach to the (rod) the higher the reading, the higher the concentration of gas.”

Several years ago, Minty began tests to see if the system could be operated from the air, first using a helicopter. However, the air around the helicopter was disturbed so much by its rotors that he was unable to obtain accurate readings.After the aircraft covers a section of the pipeline path, a computer plots the readings on a graph. Leaks show up as “mountains” of methane on the graph.

He then began working with Westpoint Aviation at Springbank Airport west of Calgary, mounting a narrow tube on the nose of a fixed-wing plane which could bring undisturbed air into the flame ionization unit. A laptop computer records the levels of methane in the air along with the exact position of the plane.

The plane’s location is determined through a global positioning system, a new technology using satellites to accurately provide an exact latitude and longitude at any given time.

“The global positioning system is what really makes this possible,” Minty says. “With it, we can narrow down the location of a leak to no more than 150 metres. From there it’s simple to find with hand-held units.”

Nova Corp. has tested the unit on it’s Alberta pipeline network and has been impressed with the results.

“To say we were skeptical is putting it mildly,” says Brian Gillis, interim leader of Nova pipeline support and maintenance planning.

“Considering the speed the plane is travelling at and the height above the pipelines it was hard to believe it could be accurate. But the tests we’ve done have been very promising.”

After successful trials, Nova contracted Airwave to cover 18,000 kilometres of pipeline to test the system.

“Right now we use walkers to provide the same intensive coverage,” Gillis says. ‘It’s very labor intensive, slow and a lot of the landowners aren’t all that pleased with us walking over their property.”

Gillis says the airborne system greatly reduces the cost, but more importantly, it’s faster.